Having corralled all of the required elements together I

decided to make a complete sample from beginning to end.

The production guys have their own methods and techniques,

This is a system that we could use in an educational setting.

Software:

Nextengine

Shoemaster

Rhino

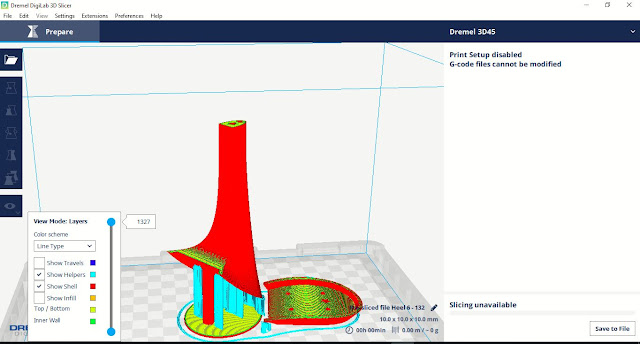

Dremel slicer

Using the scanner, I got a complete scan of the last I chose

The Next Engine scanner is a good choice.

Each last scan requires at least two hours.

From there it’s into Shoemaster to create the pattern.

Onto the 3D printer, I created a drill fixture which is just a duplicate of the top part of the heel.

The 3D45 is a good printer, the slicer software always gets

the fan on my laptop running!

Custom heel fabricated

Creating the breasted heel is a big project